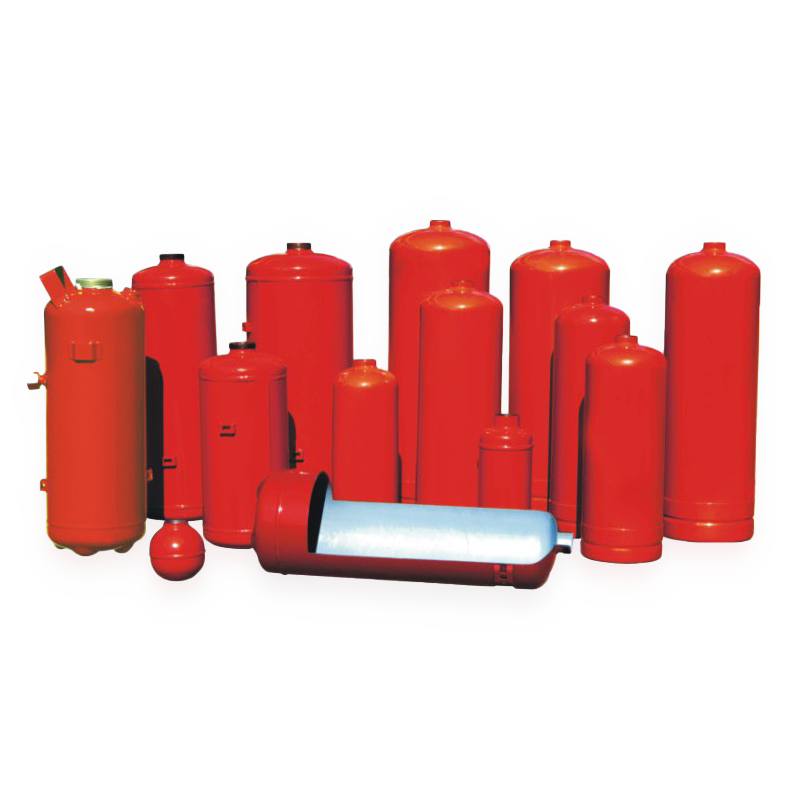

With our years of experience in the research and development of extinguisher cylinders, Firesafer can produce top-quality and all types of cylinders for customers’ needs.

Different countries have different requirements for the shape and specifications of cylinders. Firesafer has a variety of molds for the manufacture of fire extinguisher cylinder and can quickly achieve fast delivery of your order.

M Bottom

Bottom Ring

Cantonese-Bottle

Plum Blossom Bottom

Each tested by 3.0 mpa hydrostatically to ensure quality and safety without explosion

High corrosion resistance and lighter weight due to the use of carbon steel materials from raw material procurement to product molding

Whether you are in Europe, North America, South America, Oceania or Southeast Asia, we have the certifications you need

We provide valve procurement and assembly services to meet your needs for finished product procurement

Our product pass the transportation requirements for dry chemicals and wet chemicals

In addition to the standard red color, you can also customize other colors such as green, blue, etc.

We have the most efficient equipment in the industry to achieve high precision and automatic production in the process of stamping, and the bottom cover matches the barrel with a control gap of ≤0.5mm.

Pressurize the bottle body to 3.0 mpa for 1min, 100% ensure no leakage, rupture and visible deformation

Automatic coding machines enable each product produced by firesafer to be uniquely marked so that the origin of the product can be continuously tracked.

Fire extinguisher bottles and extinguishing agents generally have a life span, especially the fire extinguisher bottles, our country is the relevant mandatory end-of-life, but there are many types of fire extinguishers on the market, different types, the mandatory end-of-life will also be different, as follows.

1. if the carbon dioxide fire extinguisher, the use of the bottle is generally 12 years, as long as the 12 years, you must apply for scrapping. As long as the carbon dioxide fire extinguisher factory more than five years, and after the first repair, then every two years must be sent to a professional maintenance unit for a re-inspection.

2. if the dry powder fire extinguisher or clean gas fire extinguisher, the use of the bottle is generally 10 years, as long as the 10 years, you must apply for scrapping. As long as the dry powder extinguisher or clean gas extinguisher factory more than five years, and after the first repair, after every two years must be sent to a professional maintenance unit for a re-inspection.

3. if the water-based fire extinguishers, the use of the bottle is generally 6 years, as long as the 6 years, you must apply for scrapping. Water-based fire extinguishers factory full three years later, generally every other year must be sent to a professional maintenance unit for a re-inspection.

4. if the fire extinguisher bottle is seriously deformed, corrosion, rust and other phenomena, or no manufacturer name, the actual date of production, or the manufacturer did not obtain a production license, then generally are prohibited from use, but also prohibited from repair, must apply for scrapping.

From the material points are generally: aluminum alloy, stainless steel and carbon steel.

1.Steel cylinders are processed with different thicknesses of low carbon steel plates according to different specifications, and the cylinders with welded seams can only be used for fire extinguishers with working pressure below 2.5Mpa.

2. GB18248 seamless steel pipe for gas cylinders and GB5099-94 steel seamless gas cylinders, the cylinder body is selected from chromium-molybdenum steel: 35CrMo/34CrMo4, according to the standard GB18248, its chemical composition and mechanical properties after heat treatment in line with GB4351.2-2005 and GB5099-94.

Translated with www.DeepL.com/Translator (free version)

Red

The color of the exterior of the fire extinguisher barrel, the recommended use of red, not mandatory use of red, as long as enough eye-catching, the first time in an emergency can be found on the line.

The outer diameter of the fire extinguisher barrel should not exceed 75 mm, and the outer diameter of the fire extinguisher barrel with a handle (ring) should not exceed 85 mm.

1. The barrel of the fire extinguisher can be manufactured by welding, stretching or spinning processes.

2. The outer surface of the fire extinguisher barrel should be anti-corrosion treatment, and should be carried out in accordance with the method of 6.8.1 salt spray corrosion test on the outer surface, the test should not affect the operation and strength of the fire extinguisher.

3. The inner surface of the fire extinguisher barrel of a dollar package should be resistant to corrosion of fire extinguishing agents, and should be carried out in accordance with the method of 6.8.2 corrosion test of the inner surface of the test fire extinguisher should not rust and rust spots, the coating should not be visible to the naked eye cracking, bubbles and flaking defects.

To use the extinguisher, you pull out the safety pin and depress the operating lever. The lever pushes on an actuating rod, which presses the spring-mounted valve down to open up the passage to the nozzle. The bottom of the actuating rod has a sharp point, which pierces the gas cylinder release valve.

Fire extinguishers contain different chemicals, depending on the application. Handheld extinguishers, which are commonly sold at hardware stores for use in the kitchen or garage, are pressurized with nitrogen or carbon dioxide (CO2) to propel a stream of fire-squelching agent to the fire.

Typically, a fire extinguisher consists of a hand-held cylindrical pressure vessel containing an agent that can be discharged to extinguish a fire. Fire extinguishers manufactured with non-cylindrical pressure vessels also exist but are less common.

Carbon dioxide (CO2)

Due to its physical properties, carbon dioxide is the only extinguishing gas that is also used in fire extinguishers and fire extinguishing devices.

STEP 1: FROM STEEL ROLL TO PLATE

It all starts with steel, which arrives in our factory in large rolls. Each roll is stretched on a drawing and cutting machine, and advanced electronics are used to ensure that it is cut into sheets of exactly equal size with precision and force.

STEP 2: FROM PLATE TO TUBE

Once the roll is completely cut up, a roller turns each sheet into a round tube. Again, computers guarantee the required accuracy: each sheet is rolled into shape with exactly the right pressure.

STEP 3: WELDING

Our automatic welding machine fixes the cylindrical tube with a longitudinal seam. Special software lets us control the quality of the welding. Depending on the type of extinguisher, we may also weld mounting brackets onto it. This allows the extinguisher to be attached to a wall, for instance. Each tube is then given a lid and a bottom, including a threaded ring. This process is also fully automated.

STEP 4: TESTING THE CYLINDER

The product now has the familiar shape of a fire extinguisher. To test its resistance to pressure, we pick a number of cylinders from each batch and check to see how many bars are required to cause them to burst. This is done with water: the cylinder is first pushed flat and then inflated with water pressure. If all is well, the longitudinal seam holds and the cylinder instead cracks right next to it. This means that the material is too weak, but our longitudinal seam is of good quality. At any rate, the extinguisher does not pass the test.

STEP 5: AIR PRESSURE TEST

During the air pressure test, all fire extinguishers are exposed to one and a half times normal operating pressure. Our machines measure whether the pressure remains constant for a given period. Once it passes this test, an extinguisher is given a batch number and production date, and the Rijkstypekeur national certification. This allows the origin of the product to be traced throughout the chain. The Rijkstypekeur indicates that the product is suitable as a fire extinguisher in the indicated class (A, B, C, D, or F), which refers to the type of fire, e.g. liquid or gas.

STEP 6: INTERNAL AND EXTERNAL COATING APPLICATION

During this step, the fire extinguishers are given a coating. Foam and water extinguishers receive a coating on the inside, while the dry extinguishers do not. The inner coating prevents corrosion of the casing and is applied directly inside, with a robot linking the various process steps to each other. The latter picks up the extinguishers, shakes them firmly to ensure an equal distribution of the coating, and puts them down again.

STEP 7: SPRAY PAINTING

Extinguishers get their distinctive red coating in the powder spray paint booth. This colour is required by law. Fire hose reels may have other colours. Hose reel cabinets can also be spray painted on request in any colour the customer desires. A distinctive characteristic of this system is that 90% of the powder used is automatically recycled.

STEP 8: FILLING

Once the fire extinguisher has received a coating, it is ready to be filled with powder foam, water or carbon dioxide.

STEP 9: ASSEMBLY

This is where all the parts, from spray gun to pressure gauge, are fitted. The work is partly done by hand. The closing cap is tightened mechanically, ensuring that it is closed with just the right amount of power.

STEP 10: HELIUM TEST

To determine whether a fire extinguisher is sealed properly, we carry out the helium test. Each fire extinguisher is filled with nitrogen, supplemented with 3% of helium. Escaping nitrogen consists of relatively heavy particles that escapes slowly, but the same does not apply to helium. If the test indicates that helium is escaping, the extinguisher is discarded. This is extremely rare.

After you fill out the form, a fire equipment specialist will reach out to you within 24 hours.

The first objective will be to understand your needs, then together develop a business plan and provide you with the best pricing for you!

+86 15521103013

If you are looking for professional firefighting equipment for any of your business, Firesafer is your best choice. we can custom solutions for your business, send us your detailed requirement today.

We will contact you within 1 hours, please pay attention to the email with the suffix “@firesafer.com”.