As a leading fire extinguisher manufacturing machine manufacturer, we provide complete fire extinguisher production line turnkey solutions from A to Z. We help you to set up extinguisher manufacturing factory to produce different types of fire extinguishers, including dry powder fire extinguishers, CO2 fire extinguishers, water-based fire extinguishers, foam fire extinguishers, with capacities from 1-50KG.

We have strong technical strength and rich engineering experience in the field of fire extinguisher manufacturing and we have self-developed patented machines, which ensure our customers can start a stable and worry-free fire extinguisher manufacturing business.

We specialise in fire extinguisher production lines and have over 10 years of experience producing and customising fire extinguisher manufacturing machines. You’ll be able to interface with the most knowledgeable industry veterans at Firesafer, and you’ll be able to save money and boost your profits by getting the most appropriate solutions.

The machines we produce are uniquely identified with a production number that tracks the raw material to the machine assembly.

After assembly, the machines are tested by a team of engineers for commissioning, including no-load operation, load operation and other processes up to 24 hours.

The core components are developed by our company and enable the machine to continue working for a long period of time.

Programme design with spare parts to avoid machine breakdowns.

We are the source factory, have strict quality control process, and skip the middleman to give direct price.

We offer 24/7 support both online and onsite to minimize downtime and keep your business running smoothly.

Operation and maintenance support provided by experienced technicians.

we back each one with a comprehensive 1-year warranty that reflects our commitment to quality and customer satisfaction.

The composition of fire extinguishers can be divided into three main categories:

To manufacture a complete fire extinguisher, the above three parts need to be manufactured and assembled into a finished product.

The production of fire extinguishers is not made by a single machine, different structures of fire extinguishers need to be manufactured through different processes.

Typically, there are two types of fire extinguisher construction: deep-draw extinguishers and rolled round extinguishers.

The following is the production process for deep drawing fire extinguishers:

1.Punching:

The raw material is conveyed through the servo feeding machine to the punching machine, where it is pressed into shape by means of a customized mold.

This process produces the middle part and bottom cover of a fire extinguisher cylinder.

2.Deep drawing:

Steel or aluminium sheets are deep drawing into cylindrical shapes.Deep drawing is a specialised metal forming process, The metal blank is placed on the die and then pressed downwards with a punch.The force of the punch causes the metal to flow into the shape of the mould, resulting in a cylinder with a closed base.This part produces the middle part of the fire extinguisher.

3.Welding:

Attach the top and bottom of the fire extinguisher by welding them together. This is typically done using a combination of TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding techniques to ensure a strong and leak-proof joint.

4. Leak testing, hydraulic testing, Burst Testing:

Leak testing and hydraulic testing and burst testing of the welded cylinder.

5. Surface Finishing:

Once the extinguisher cylinder has passed the inspection, the next step is to polish the surface of the extinguisher cylinder shell to make it smoother. This process is normally done by a shot blasting machine.

6. Painting Line:

After grinding the fire extinguisher cylinder, the fire extinguisher will need to be put on the spraying line and the paint will automatically stain the fire extinguisher through the machine.

7. Filling, assembling, labeling and packing

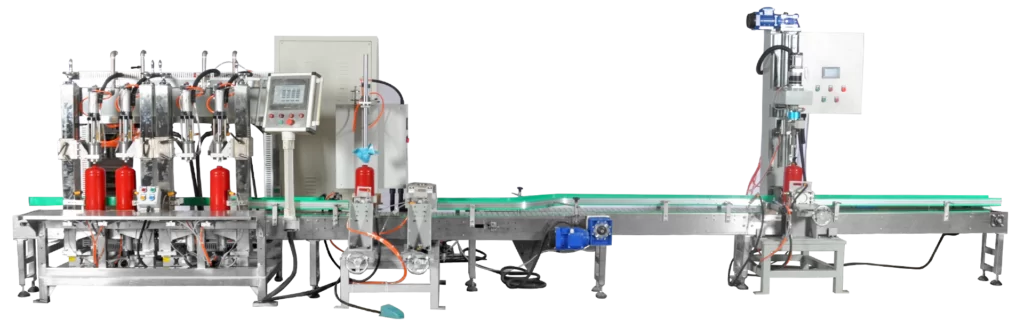

Next we need to fill the fire extinguisher with fire extinguishing agent (dry powder, carbon dioxide or foam, etc.) by filling the machine. After the filling is completed, the valve is automatically tightened, filled with nitrogen, tested for gas tightness, and finally labeling and packing.

For more details, please contact firesafer.

Fire extinguisher filling is the most critical step in the manufacture of fire extinguishers.

Most of our customers start their projects by purchasing filling lines and other accessories and assembling them locally, which greatly reduces the initial investment cost. This approach is very friendly for most companies.

Investment in a fire extinguisher manufacturing line can range from $10,000 to $5,000,000, depending on the company’s production capacity, automation needs, project budget and other factors.

Contact our experts for a customized solution.

If you want to get the most suitable solution, you need to provide us with the following information to design a solution for you:

After you fill out the form, a fire equipment specialist will reach out to you within 24 hours.

The first objective will be to understand your needs, then together develop a business plan and provide you with the best pricing for you!

info@firesafer.com

+86 15521103013

We will contact you within 1 hours, please pay attention to the email with the suffix “@firesafer.com”.