The production of fire extinguishers is not made by a single machine, different structures of fire extinguishers need to be manufactured through different processes.

Typically, there are two types of fire extinguisher construction: deep-draw extinguishers and rolled round extinguishers.

The following is the production process for deep drawing fire extinguishers:

1.Punching:

The raw material is conveyed through the servo feeding machine to the punching machine, where it is pressed into shape by means of a customized mold.

This process produces the middle part and bottom cover of a fire extinguisher cylinder.

2.Deep drawing:

Steel or aluminium sheets are deep drawing into cylindrical shapes.Deep drawing is a specialised metal forming process, The metal blank is placed on the die and then pressed downwards with a punch.The force of the punch causes the metal to flow into the shape of the mould, resulting in a cylinder with a closed base.This part produces the middle part of the fire extinguisher.

3.Welding:

Attach the top and bottom of the fire extinguisher by welding them together. This is typically done using a combination of TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding techniques to ensure a strong and leak-proof joint.

4. Leak testing, hydraulic testing, Burst Testing:

Leak testing and hydraulic testing and burst testing of the welded cylinder.

5. Surface Finishing:

Once the extinguisher cylinder has passed the inspection, the next step is to polish the surface of the extinguisher cylinder shell to make it smoother. This process is normally done by a shot blasting machine.

6. Painting Line:

After grinding the fire extinguisher cylinder, the fire extinguisher will need to be put on the spraying line and the paint will automatically stain the fire extinguisher through the machine.

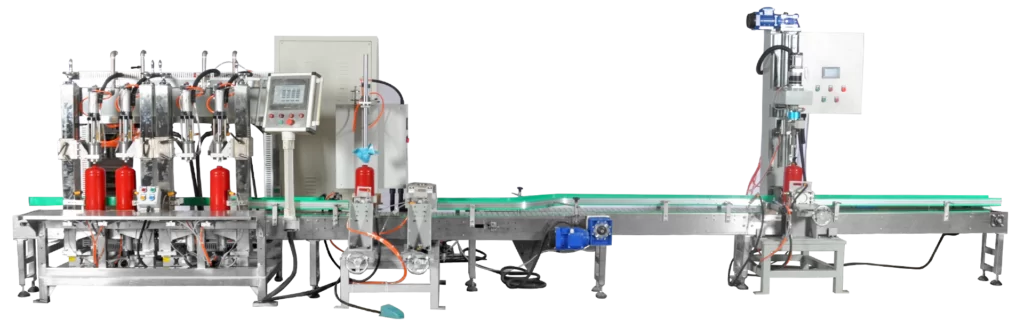

7. Filling, assembling, labeling and packing

Next we need to fill the fire extinguisher with fire extinguishing agent (dry powder, carbon dioxide or foam, etc.) by filling the machine. After the filling is completed, the valve is automatically tightened, filled with nitrogen, tested for gas tightness, and finally labeling and packing.

For more details, please contact firesafer.